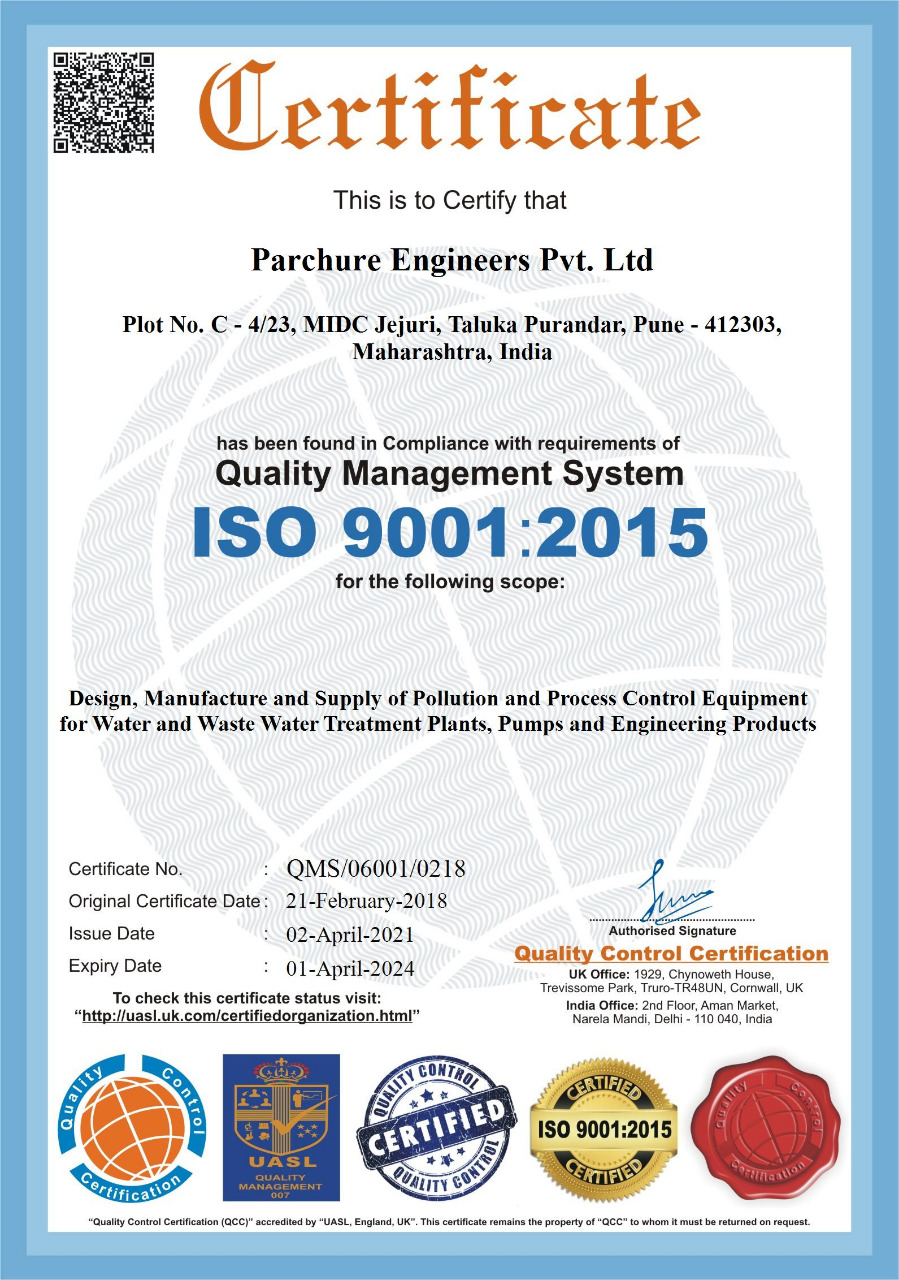

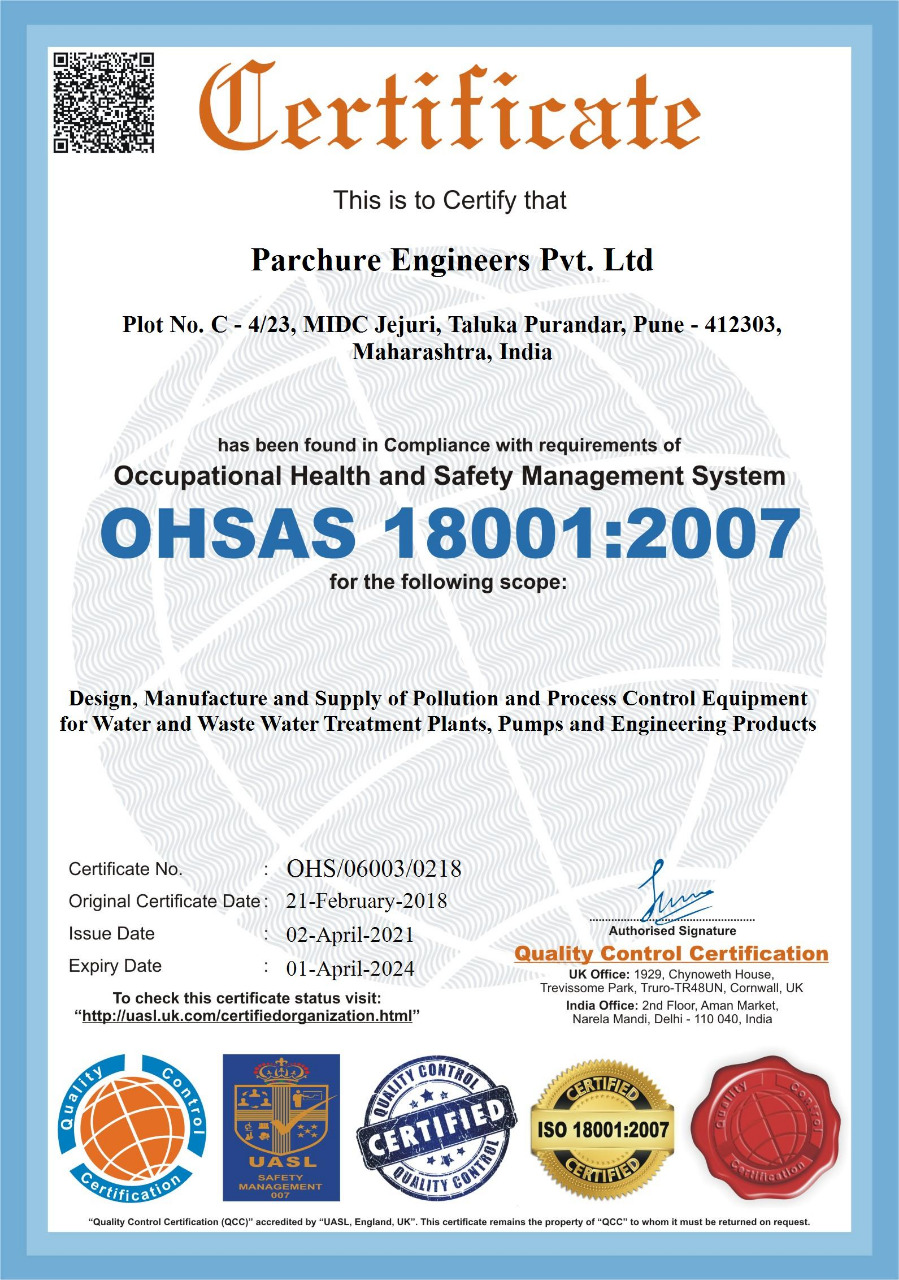

Quality Assurance

- Home

- Quality Assurance

Quality Standards

Quality is not a destination it is a journey. A Journey of identifying and maintaining professional excellence in all our endeavours.

- Indigenously Developed Products. All products are unique and we do not believe in reverse engineering practices.

- Adequate Infrastructure for manufacture of all types of equipment

- Design team with use of latest design software for designing like AUTOCAD, STAAD and Solid Works qWPS Qualified Welders

- In house production facilities for complete quality control.

- PMI Facility for Material Grade Verification , Dye Penetration and Acid Pickling

Quality Standards

- Positive Metal Identification on all raw materials. ( PMI Gun Facility Available )

- NABL Accredited Laboratory Test Certificates obtained from vendors and tests conducted internally by our QC Department

- Separate Storage and Tagging of AISI 316L , AISI 316 , AISI 304 , AISI 410 and Mild Steel Sections.

- Inventory management philosophy is Project Based Just in Time Inventory to reduce intermixing of materials of different grades

- Acid Picking and K2 Wash Process on Welded Stainless Steel Joints

- Passivation and Thorough washing procedure for removal of chemicals and other dirt and grease.

- Unique Bespoke Production Management System developed for identification and tracking of components and Archive method production record to maintain product information for 5 years from manufacturing.

- Use of computerised simulation techniques for rating product performance during design.

- Excellent consultancy support for STAAD and structural analysis of designs.

- Calibrated measuring instruments for precision fabrication

- WPS Qualified Labours for Excellent welding quality and finish.

- Argon Welding Process is exclusive used in manufacturing.

- Skilled Manufacturing Team with experience of minimum 5 years in our own production.

- Trusted Vendor Network to minimize risk of compromising materials quality and grade.